Industry leading Innovation

Innovation in the process of product design and production with innovative ideas increases competitive advantages; Therefore, it is necessary to support domestically produced goods and products, to support consumers and to pay attention and satisfy consumers.

Long-term trust-based relationships

Creating production infrastructure and supplying high-quality raw materials and sustainable production on an industrial scale will gain trust and replace similar foreign brands.

Commitment and focus on continuous product improvement

Continuous improvement of quality is the introduction of customer orientation, the most important factors of production growth are improvement of production quality and attention to innovative production, which will lead to market development and business dynamics.

Having scientific and executive potential

The use of academic and experienced experts is done with the aim of providing the highest quality biotechnological products in the world based on the most advanced technology available in the market.

products categorization

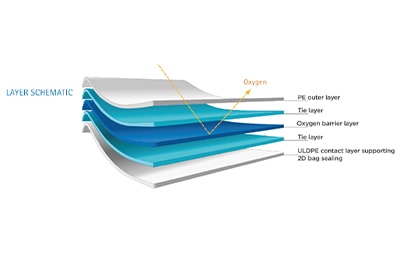

The unique features of Zist Bag

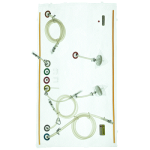

Very low setup time during production due to elimination of lengthy CIP, SIP, complex validations process

Saving time

The cost of starting and initial establishment is much lower due to cheaper tanks and also the elimination of sterile and washing systems, the elimination of utility piping.

Low setup cost

Very easy user interface due to the elimination of many pipings and valves

Agile and flexible system

Very low maintenance cost

Due to the elimination of diaphragm valves, the reduction of the use of mechanical equipment for steam control and the lack of use of mechanical flood, partial PM tests are required.

Low setup cost

Reducing the high costs of continuous production of steam and pure water for sterilization (SIP) and washing process (CIP). Example: For the washing process of a 2000-liter tank, approximately 3200 liters of PW water and 1500 liters of WFI water are used, and for the sterile process, 400 kg of clean steam is used.

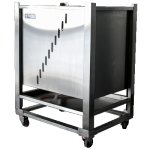

Small production space required

The space of the production clean room is very small due to the lack of complex piping and the elimination of a number of equipments, for example, the elimination of CIP Station tanks, the elimination of SIP Skid and PSG.

Danesh Bonyan Zist Barg Polymer Company was founded in 1401 in order to produce advanced and technological equipment for drug production in the pharmaceutical industry, such as the production of disposable bags, bags for storage, cultivation, preparation, as well as storage platforms for bags, View for CE Bioreactors, standing bioreactors were established to obtain ISO 9001 certificate, export certificate and knowledge certificate in this short period of time.

Zist Bag Polymer is the first company in Iran that has developed the production of single use systems under the Zist Bag Polymer brand.

The products of this company replace the traditional systems of drug production in steel tanks. Pharmaceutical steel tanks require a very large space for production, high initial investment, a lot of water and energy resources; which makes setting up a drug production site costly and time-consuming.

The new single-use systems without the need for water and energy resources and much less production space have caused drug production sites to be created much faster and at a lower cost, which has made this equipment a special place in the industry during the Corona epidemic. have medicine

If you intend to order and buy ZistBarg products, our consultants are by your side. Detailed and comprehensive and technical advice will be provided to you by the experts of the sales department. You can contact our experts by referring to the “Contact Us” section.

Also, our experts will contact you by registering a request in the form in front of you.

If you do not find the answer to your question, contact us through the opposite form.

Get guidance and advice

We Help You Simplify the Process

Our Customers